- Automotive

- Aviation

- Building & Construction

- Corporate

- Corrections & Prison Systems

- Evaporative Cooling

- Farm & Agriculture

- Home & Residential

- Hospitality & Dining

- Military & Government

- News

- Outdoor Work Applications

- Pets & Animals

- Safety

- Small Business & Trades

- Sports & Outdoors

- Warehouse & Industrial

Are hot trucks threatening the health and productivity of your workers?

Summertime can create grueling conditions for workers tasked with unloading shipping trucks. Whether the truck has spent days on the highway or was simply docked at a shipping facility for an extended period of time prior to unloading, temperatures inside the shipping container can be downright brutal.

These trailers function as mini ovens when it gets hot out, trapping radiant heat from the sun and becoming pressure cookers when outside temperatures reach high levels. In fact, temperatures inside trailers can often exceed 130°F, making it extremely challenging for workers to perform essential tasks such as loading, unloading, throwing protective tarps over cargo and securely strapping cargo down.

It is critical for operations managers to be aware of the risks to workers loading and unloading shipping trucks in extreme heat. These hot conditions not only present safety hazards, but they also negatively impact the productivity of your team.

Health Issues Associated with Unloading Hot Shipping Trucks

By far, the most pressing issue caused by the excessive temperatures involves the health risks experienced by workers. In particular, your employees face a significant risk of heat-related illness. This may manifest in many forms:

- Dehydration – It’s common for workers to sweat profusely when unloading hot trailers, resulting in dehydration. Dehydration occurs when the body is unable to replenish the fluids it loses. Often, this is the precursor to more serious heat-related issues.

- Heat Cramps – Dehydration can often deplete your sodium and chloride levels, causing heat cramps to develop. Common signs of heat cramps include intense muscle pain or spasms in the abdomen, arms or legs.

- Heat Exhaustion – Heat exhaustion is more serious than heat cramps and is often accompanied by symptoms which may include profuse sweating, dizziness, chills, fainting, nausea or vomiting.

- Heat Stroke – This is the most serious form of heat-related illness and should be considered a medical emergency. Failure to treat heat stroke in a timely manner can result in damage to internal organs and may potentially be fatal. Heat stroke occurs when your body is no longer able to control its core temperature. Once your body temperature rises above 104°, you may experience symptoms such as seizures, confusion, or decreased mental activity.

Productivity Issues Associated with Hot Shipping Trucks

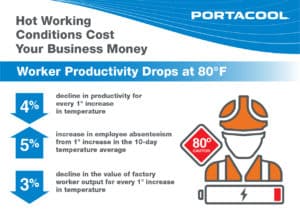

While the health issues discussed above represent the most serious risks associated with workers loading and unloading extremely hot trucks, you also may potentially face productivity issues which will hurt your profitability. It’s common for shipping trucks to get so hot that workers are forced to work in extremely short segments with large breaks in between to prevent the development of heat-related illness. This results in shipping containers being loaded and unloaded at extremely slow paces.

These hot conditions can also increase the likelihood that your workers will make errors. Studies have demonstrated that employees make roughly 12 times as many errors when the ambient temperature reaches 95° compared to when it is at 80°. With shipping trucks often reaching temperatures as high as 130°, the number of errors will rise steeply. This can result in the contents of a shipping truck becoming damaged in transit due to errors in the steps taken to secure these items when they are loaded, costing your business a lot of money.

Evaporative Coolers Can Help Your Workers Minimize Health and Productivity Risks

Evaporative coolers provide an affordable and effective way to minimize these health and safety risks with your employees. Portable evaporative coolers draw in hot outside air. As this air comes into contact with saturated cooling pads called evaporative media, it triggers an evaporation process which can drop the air temperature as much as 30°F. This cooler air is then blown throughout the space to provide a more comfortable ambient temperature.

Because evaporative coolers are portable, you can easily move them around to provide cooling in the exact areas of the truck where workers are loading or unloading. This results in several important benefits:

- Significantly reduces the risk of heat-related illness

- Reduces the length of break times, allowing employees to work at a faster pace

- Reduces the level of employee absenteeism that typically occurs during excessively hot summer working conditions

- Saves your business thousands of dollars in medical costs associated with treating employees for heat-related illness

Keep Your Shipping Trucks Cool with a Portacool

As the industry leader in evaporative cooling technology, Portacool can deliver the effective results your workers need. Our evaporative coolers are made locally at our Center, Texas manufacturing facility. In addition, all evaporative media for your Portacool is also made by us, so they are built to fit the exact specifications of your machine. This provides optimal cooling benefits at all times.

With a wide range of evaporative cooler models, you can easily find the right Portacool to address your specific needs. You’ll also benefit from our best-in-class warranties and customer service. If you’re unsure which option is right for your business, you can get customized recommendations from our team to ensure your workers stay safe, comfortable, and productive when loading and unloading trucks in the peak summer heat.

Visit a local retailer or contact us today to learn more about our evaporative coolers.